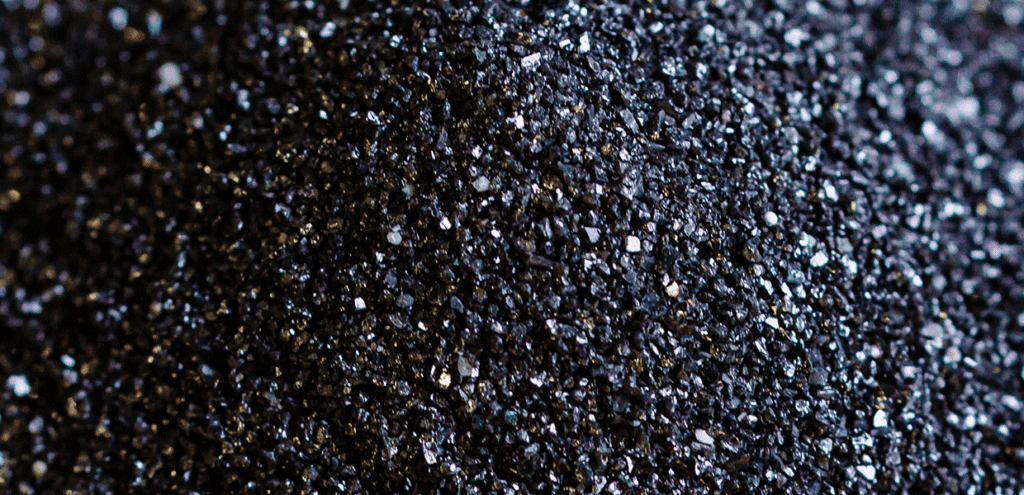

Choosing the Right Blast Media for Your Surface Preparation Needs

The first step in selecting the right blast media is understanding the compatibility between the media and the surface you’re working on. Different materials respond differently to various types of media.

Learn more about how the right or wrong media can affect your results.

Surface Preparation for Cerakote Application

Learn how to properly prepare your parts for Cerakote application. Surface preparation is key to achieving optimal results. Clean and inspect your parts, and achieve the proper surface finish through abrasive blasting.

Suction vs Pressure Sandblasting Systems

Empire ProFinish cabinet is a high-performance cabinet built with execution and versatility in mind. It sets the standard for industrial applications and features a tunable reclaim system and dust collector, which not only helps you save on media consumption, but it also removes dust, oversize particles, and fines from your working mix

Blasting 101: How to Size Your Blast Nozzle/Hose

Selecting Blast Nozzle Size with most man-made machines, eventually parts will break down, stop working, and need to be replaced.

We help you understand blast hose wear and tear

Surface Refinishing Requirements and PMB Aerospace Applications

The U.S. military and the commercial airline industry require a variety of quality controls and standards for removing old paint, adhesives and other coatings off composite panels—or an entire aircraft—by a process called plastic media blasting.

Vibratory Deburring Process Development

Removing metallic sharp edges, nicks and burrs is no mystery in production operations such as machine stamping and other post manufacturing processes. The unwanted material is removed by a process called deburring and is usually performed using some type of hand tool or other machine that is often time consuming and labor intensive.

Powder Coat Removal Test | Garnet vs 10x Engineered Materials

Powder Coat Removal, which abrasive is better suited for the job? In our quest to determine the best abrasive blasting media, we decided to start doing side-by-side tests in order to get a more accurate look at performance. We chose two popular contractor media – Garnet and the new 10x Engineered Materials (10x for short) and got some surprising results.

5 Reasons to Outsource Your Metal Finishing Process to Rodeco

Sometimes, it makes sense to outsource it to trusted specialists. If you want to save time, money, and hassle, look into your options for outsourcing metal finishing.

5 Tips To Improve Your Vibratory Finishing Process

If you’re not getting great results from your current process, such as a less labor-intensive workload or a desirable end product, you’re not alone.

Here are our top five recommendations for a better vibratory finishing process.

Glass Bead Blasting v. Ceramic Bead Blasting–Which One is Right For Your Needs?

Glass Bead vs Ceramic Bead Blasting, which abrasive should you choose? When you need an abrasive for your next blasting project, you have several options. Two of the most common abrasives are glass beads and ceramic beads. Learn about both media and see which is right for you.